PPTC (Polymer Positive Temperature Coefficient) temperature sensitive resistors have already become vital elements in today's motherboards, notebook, mobile phones and other consumer electronics devices. With years of experience in the SMD PPTC manufacturing processes, Polytronics said it can help to improve user peripheral compatibility, reduce subsequent manufacturer maintenance costs, and increase overall added value for the transition between USB 2.0 and USB 3.0 with PPTC and super low rho (SLR) PPTC components.

Polytronics is focused on PPTC research and manufacturing

Polytronics was founded in 1997 and is based in Taiwan's Hsinchu Science Park. The company mainly produces PPTC temperature sensitive resistors and thermal substrates, which are sold worldwide under Polytronics' own Everfuse brand. Types of PPTC include: SMD (surface-mount device), ALD (axial leaded device), RLD (radial-leaded device) plug-in elements, and disc-shaped and other customized elements.

SMD-type components are currently the mostly widely used elements, and are mainly used in motherboards, mobile phones and consumer electronic devices, and in recent years, have been introduced into Lithium battery protection designs; ALD-type are widely used in various types of Li-ion batteries; RLD plug-in pin elements are mainly used in MB/GC and industrial electronics; and disc-shaped elements are used in cylindrical rechargeable batteries. Other products include polymer ESD (static) protection elements, one-time fuses, thermal conductive CCL and thermal interface material (TIM) designed for use with PCBs in LED lighting and LED TVs.

Assistant manager of Polytronics' Technical Development and Service Center Xie Junbai explained that Polytronics' PPTC temperature sensitive resistors are made of polymer and conductive particles, with two electrodes connected to the plug-in RLD type. The SMD type is produced using Polytronics' patented PCB manufacturing process. Under ordinary current conditions, devices are in a low-resistance state; as soon as the current conditions change, the joule heating effect produces a massive jump in resistance, causing the circuit to be broken, thereby protecting further circuits. Once the situation returns to normal, conductivity across the circuit is immediately restored, and the process can be repeated many thousands of times. For this reason, PPTC elements have replaced one-time fuses in recent years, becoming vital over-current protection elements for motherboards, notebook, consumer electronics devices and mobile phones.

Strict adherence to USB 3.0/2.0 compatible specifications, outstanding price/performance ratios in PPTC products for a commercial edge

Comparing the USB 3.0 standard with its predecessor USB 2.0, power delivered has increased to 900mA in USB 3.0, therefore at full load the motherboard or hub is slightly reduced from the original 4.75V to 4.45V. As devices which receive power through USB must be able to operate normally at 4.00V, as well as with current limitations such as transient current and motherboard sleep or hibernation modes, the USB 2.0, USB 3.0 and HDMI specifications all propose designs using PPTC or OCP ICs as over-current protection elements, in order to comply with the UL-60950-1 Limited Power Source (LPS) and UL 1434 standards.

If PPTC elements are compared to semiconductor switch OCP ICs, other than their somewhat slower reaction times (in the millisecond rather than microsecond range), PPTCs are superior in most other respects, no matter whether the issue is reusability, maximum fault current (>100A), or maximum fault energy (800W); moreover, their low impedance, zero electrostatic susceptibility design and comparatively lower cost make PPTC elements favorites with engineers for designing over-current protection circuits.

Polytronics provides a complete line of PPTC products, which work with customer design requirements, while meeting USB 3.0 over-current protection standards. The small size SMD 1206 (0.12-inch by 0.06-inch) and PPTC 1210 (0.12-inch by 0.10-inch) provide protection for one to two USB ports; these over-current protection elements are both capable of maintaining full current load at temperatures above 50-degress C without operating, avoiding erroneously tripping the PPTC element as a result of thermal derating.

Although the voltage requirements for the power supply terminal are somewhat reduced in USB 3.0, Polytronics still recommends using the SLR, in order to ensure that voltage drops in the PPTC at full current load do not exceed 0.1V, particularly for rear USB ports in desktops; this not only ensures greater compatibility with USB 2.0 devices, but also leaves more design headroom for motherboard circuits. A typical Intel 5-series or AMD 8-series motherboard provides 10-14 USB ports, with a single or dual port requiring only a single PPTC; at least 5-7 PPTC elements are therefore needed, added to 1-3 elements for a single 1394 port, with the result that an individual motherboard can use as many as 16 PPTC elements.

SLR (super low rho) for increased current and improved peripheral compatibility

Polytronics' vice president of sales Zeng Wenchang explained that breakthroughs in SLR (super low rho) materials for Polytronics' surface-mount devices (SMD) mean that the company's newly launched SLR PPTC has the following advantages over most conventional PPTC elements:

Super low resistance/low voltage drop: Using a 1.5A element, Rds (ON) approaches 110mOhms with an IC under a current of 1A, while the figure for the Polytronics SLR element is only 40mOhms; this allows the consumer to use a longer USB cable and increases compatibility with peripherals that require large amounts of current.

High current: Ordinary PPTC and over-current protection (OCP) ICs are limited by the fact that their internal resistance is unable to cope with high-current products; the SLR series offers a choice of the 1206 3A or 1210 3.5A or higher elements, so that users can connect external USB hubs without external power sources. SLR products are also compatible with the latest USB battery charging v1.1 specification, under which USB ports must supply 1.5-1.8A of charging current.

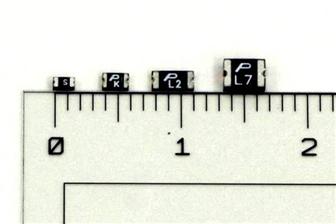

Ultra-small dimensions: Polytronics is the first manufacturer to mass produce 0805/0603 PPTC elements, as well as offering two sizes of SLR PPTC product; the 0603 is able to supply 1.5A current suitable for use with USB 3.0 products, while the even smaller 0402 SLR PPTC is also at the prototype stage.

Polytronics' solutions are compatible with the latest standards, including U1434 and UL/IEC 60950-1 2nd Edition LPS 8A current five second cutoff operations.

Zeng added that SLR solutions originally evolved from the development of low resistance SLD axial PPTC elements for Lithium mobile phone batteries; these products only exist thanks to the combination of the unique properties of the material and Polytronics' own experience of PCB and SMD manufacturing processes. Polytronics hopes to utilize these materials to develop products which are ultra-thin, possess even smaller dimensions (0805, 0603, 0402) and can cope with correspondingly high working currents, in order to provide over-current protection for high-spec mobile phones and other handheld electronic devices.

Starting out with the USB 3.0 specification's requirements for electrical characteristics, Polytronics began to promote uses for SLR both domestic and internationally in 2009. Competition in Taiwan's motherboard market is particularly fierce, with the result that the major motherboard manufacturers have been highly enthusiastic about the introduction of SLR, including Asustek Computer and Gigabyte Technology, as well as key notebook OEMs, have already introduced SLR PPTCs into their products, with designs featuring 1206 or smaller size PPTC elements.

High patent thresholds leave the competition standing

Zeng pointed out that Polytronics has patents for everything from the materials and structure to the manufacturing process. For this reason, even though many China-based manufacturers are developing similar products, a large number of technological breakthroughs are still required when working with conductive ceramic filler in PCB process, making the prospect of competing products coming out unlikely in the short term, giving Polytronics an undoubted advantage in this area.

Polytronics has high hopes that the increasing use of USB 3.0 will help to popularize SLR PPTCs. Zeng explained that most manufacturers assess passive elements in terms of price, supply and quality. Polytronics is working to break through many manufacturers' ill-conceived design philosophy of "enough will do"; the firm's SLR PPTC products allow desktops, notebooks and consumer electronics devices to become less power hungry and more compatible, helping to reduce subsequent compatibility problems, not to mention customer service and RMA costs.

Polytronics' SMD PPTC products took a nearly 70% share of the market in 2009, with production capacity in 2010 standing at around 200 million units per month, and monthly shipments of SLR series products account for around 10 million units, just under 10% of overall shipments. Zeng said he believes that this figure will gradually climb as first-tier motherboard manufacturers and major notebook OEMs begin using these products, which should be the mainstream within 2-3 years.

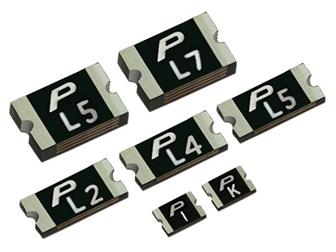

Polytronics' PPTC products: SMD SLR series

Photo: Company

Miniaturized design: Polytronics' first 0805 and 0603-size SMD PPTC components are also available in the same ultra-low resistance versions. The 0805 and 0603 models can be used to implement 2A or 1.5A high current protection respectively.

Photo: Company

| Comparison with existing products | |||

| Product | Ihold (A) | R1max (mΩ) | Max Voltage |

| SMD1206P150TFT | 1.5 | 120 | 0.120 |

| SMD1206P150SLR | 1.5 | 55 | 0.055 |

| Comparison with over-current protection ICs | |||

| Product | Continuous Current (A) | Typical | Typical Voltage |

| Current Limiting Switch | 1.5 | 110 | 0.110 |

| SMD1206P150SLR | 1.5 | 40 | 0.040 |

Ultra-low resistance, ultra-low voltage drop: Ultra-low resistance materials mean that peripherals can receive higher voltages while working under high-current conditions.

Source: Company

DIGITIMES' editorial team was not involved in the creation or production of this content. Companies looking to contribute commercial news or press releases are welcome to contact us.