According to Accenture, 95% of manufacturing firms worldwide intend to initiate IIoT-based operations in the next three years, in hopes of automating production monitoring to replace conventional process and implement preventive maintenance. 73% of the companies polled, however, admit that their IIoT plans have yet to make any progress.

Commonly, once a manufacturer has managed to allot a budget, accommodate physical installation demands, overcome wiring and other fitting issues, deploy ready-made equipment monitoring systems (comprising IPC and DAQ modules and signal conditioning circuits), and eventually start acquiring data, the absence of resources and capability to follow up with meaningful data analysis and visualization actually prevents development of a prototype for evaluation.

According to Zake Lin, ADLINK IST's Product Manager for Connected Equipment, even the best-planned IIoT implementations often end up languishing, since operators, even after struggling to meet significant requirements or investment in labor, resources, technology, and operating capital, find themselves stuck in a long unproductive evaluation period, unable to make any further progress.

ADLINK DXS IoT Digital Experiments as-a-Service enables smooth transition to IIoT function and valuable data access with minimum upfront investment

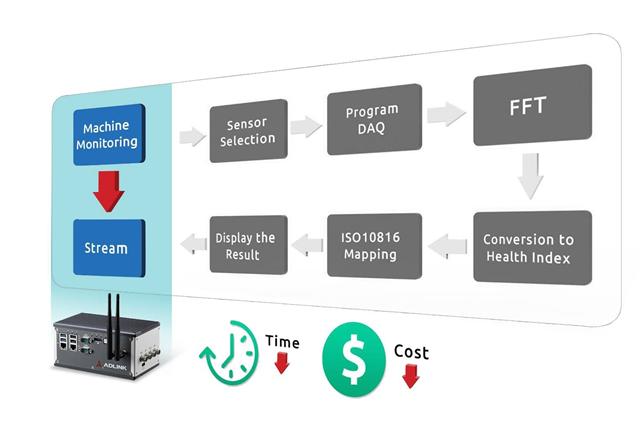

Unlike most available solutions pieced together from disparate standalone elements, ADLINK's MCM-100 provides an all-in-one solution that can directly connect with an accelerometer or other sensor to acquire machine status data, perform real-time analysis of the gathered data, upload the results to data centers, and connect to upper level ERP/MES systems for further data management. Moreover, ADLINK provides cloud-based solutions enabling web dashboard, warning issuance, information security, and OT/IT conversion capabilities cooperating with the MCM-100 to take complete advantage of valuable data.

As well, to break through bottlenecks and fully achieve IIoT-based objectives, ADLINK has evolved beyond conventional product sales models by, first, attaining a clear understanding of user needs and then combining system integrator (SI) resources in concert with the MCM-100, defining implementation details and expected results. Next, an ADLINK DXS package is formulated and a pilot run launched to establish the MCM-100's efficient acquisition of equipment behavior data and machining parameters, for real-time analysis. Generation of warnings and other notifications can also be configured. Once the evaluation results are available, the user can precisely calculate ROI, and work with ADLINK to assemble the ideal solution and inaugurate large-scale deployment.

ADLINK's planning expertise enables machine makers and factory equipment management and service operators to reap the full benefits of the MCM-100. In one example, a major electronics assembler relies heavily on CNC cutting tools for production. Consequently, any failure of the tools represents considerable downtime with accompanying drop in throughput., The assembler wished to incorporate ADLINK's MCM-100 solution to prevent unexpected cutting tool failure from generating machining defects. A DXS-based pilot run was implemented, with an accelerometer delivering detailed machine behavior data, in this case vibration measurement, to the system. The MCM-100 performed detailed analysis of the acquired data, and was able to, based on the results, predict upcoming tool failure. The operator was then able to perform preventative maintenance, replacing the CNC cutters before costly downtime occurred. The test system was thus able to obtain effective, meaningful results with a minimum of expense and risk. Upon evaluation of the results, large-scale deployment was undertaken, and the operator was able to successfully build up its cutting tool monitoring system. As a final confirmation of effectiveness, zero machining defects have arisen since the system has been up and running.

Five key approaches to perfect IIoT project implementation

In sum, Lin concluded that for an IIoT project to achieve success, five key elements are necessary.

- Think big: Manufacturers can start by considering problems to be solved, then ramp up to determining processes to be changed and the benefits they hope to achieve, in order to generate the maximum business value possible.

- Start small: Operators can, with minimal up-front investment, take advantage of digital experimentation to verify that valuable information can be obtained by collecting and analyzing data and whether the projected outcomes, such as improved production quality and reduced labor costs, can actually be achieved.

- Keep trying: Users should become comfortable with the idea of making mistakes, get accustomed to learning from them, and develop the resilience to keep trying.

- Build an ecosystem: The IIoT value chain encompasses protocols and connections, security, data streaming, equipment management, power control, data transfer, machine learning/deep learning, edge analysis, cloud computing and many other complex links. Without a complete ecosystem, an individual supplier will not be able to manage everything on its own.

- Recognize the facts: The ultimate goal of IIoT implementation is to explore data and identify valuable information, rather than simply perform technological experiments.

ADLINK DXS IoT Digital Experiments as-a-Service enables smooth transition to IIoT function

DIGITIMES' editorial team was not involved in the creation or production of this content. Companies looking to contribute commercial news or press releases are welcome to contact us.