Looking back through the year, smart production can be regarded as a global development trend. Covid-19 outbreak has hit the global manufacturing supply chain. Although the labor shortage has led to the serious decline in production across the industry, the epidemic has driven the demand for "smart manufacturing" and is expected to transform the production model with a vision of the "Smart Factory" of the future.

A Smart Factory concept is centred around the confluence of digital transformation and intelligent manufacturing trends. It implements the key value of Industry 4.0 with automation, real-time data, connectivity, embedded sensors and machine learning which will transform the traditional production model into a highly customized and intelligent way. The notable component driving these trends is the AI of Things (AIoT).

AIoT is the potential synergy lies in this intersection of IoT (or IIoT; Industrial IoT) with AI. At its core, the crucial characteristic defining the AIoT promise (and therefore the Smart Factory) is the massive proliferation of intelligent, automated decision making capabilities across the IIoT network. Decisions begin with the analysis of data, so enabling data analytics with an AIoT approach can be a logical and attractive starting point with relatively low initial investment.

Current data analytics capabilities already possess good ROI in their inherent ability to help improve the productivity, quality, yield, or optimise the cost of producing products. An AIoT-enabled data analytics set-up augments these benefits by generating useful data-driven insights that can be used to help the manufacturing system learn from, be optimized, and generate higher performance, or to help users make better decisions. AIoT represents a fundamental paradigm shift for the industry and a massive step towards the vision of achieving the Holy Grail of zero DPPM manufacturing while boosting quality, yield and cost standards across the entire electronics manufacturing value chain.

Let's look at one example. Wire Bonding is one of the critical processes in semiconductor assembly that can generate defects, and quality assurance via sampling to spot defects at the factory gate is a typical step. However, sampling has its risks, as defective components can escape detection, with serious liability issues when lives are put at risk. Root cause analysis is also very onerous when defects are detected, massive data points are typically involved making traditional analysis very difficult. The cost of product recalls can also be very costly.

The relentless chase towards zero DPPM is thus understandable but a hard vision to achieve using traditional means. An AIoT-enhanced data analytics approach for the Wire Bonding Process flips this scenario on its head, with quality data points analysed in real time. It provides on time, high integrity data points which are crucial for accurate and timely analysis. Out-of-control process anomalies, and defect generation predicted and automatically corrected before output quality is affected. Predictive, automated decision making such as this - 100% quality assurance without Human Intervention - would totally revolutionize and transform current industrial approaches toward Quality Control.

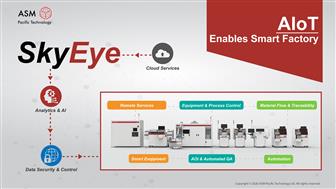

Realizing the vision of zero DPPM, ASMPT's newly developed IIoT platform software- SkyEye is ready to drive the "Smart Factory." SkyEye manages and brings insights and intelligence across your macro and micro automation, process equipment, autonomous inspection and metrology. It revolutionized operation management through its remote functionality equipped with AR and VR capability; for off-site assistance, troubleshooting, recovery and process development.

Connectivity to ASMPT AIoT Cloud Services provide End to End Data Analytics Life Cycle & Knowledge Management for your AI enabled manufacturing. With an AIoT approach properly put in place, the entire manufacturing value chain can be increasingly equipped with new ways to develop, innovate, and manufacture. The ultimate goal is to produce faster, better and more cost- effective and flexible, without compromising increasingly stringent standards of safety and quality. Please visit ASMPT official website for full text.

ASMPT's newly developed IIoT platform software- SkyEye is ready to drive the Smart Factory

An AIoT-enabled data analytics set-up augments these benefits by generating useful data-driven

DIGITIMES' editorial team was not involved in the creation or production of this content. Companies looking to contribute commercial news or press releases are welcome to contact us.