Over its 25-year history, Prosemi has become a trusted source for testing electronic components among some of the world's largest CEMs and OEMs. As the largest test house in Southeast Asia, Prosemi is equipped to address the risks of counterfeit electronic and substandard components, which pose significant risks to the electronics industry, as they may compromise the functionality, reliability, and safety of devices. To go beyond baseline testing and assessment, Prosemi invests in the latest quality solutions and technology, as well as various certifications, to set the highest standards. This is where the C-mode scanning acoustic microscopy (C-SAM) tool is largely beneficial for customers concerned with defective, cloned, renewed, or recycled parts.

Deploying the C-SAM Tool

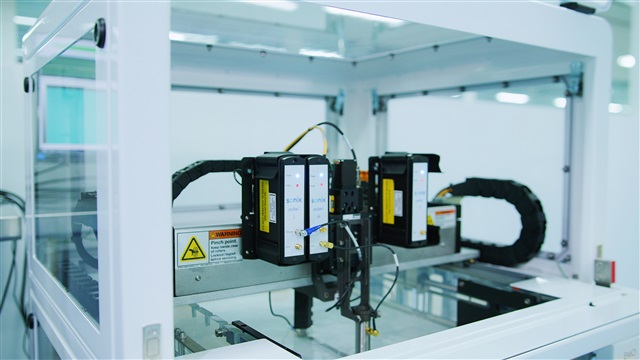

To address the risks in the market, the industry has developed several standardized testing methods, which include destructive analysis. Destructive analysis is particularly effective in the recycled and remarked areas. One way to conduct an analysis is with C-SAM, a destructive testing tool where parts are submerged in deionized water.

C-SAM Tool

How C-SAM Works

C-SAM utilizes high-frequency ultrasound waves to inspect and create images of the internal structures of samples, providing valuable insights into their properties. This technique is commonly used for quality control and failure analysis in numerous industries, including electronics, semiconductor manufacturing, aerospace, and materials science. It is particularly valuable for counterfeit analysis due to its ability to identify anomalies and inconsistencies in the packaging and construction of semiconductor components.

By using C-SAM, the internal structure of the packaged semiconductor can be visualized without physically opening them. The tool tests for internal voids or delamination between molding to die and molding to lead frames. By comparing these images with known authentic components, any deviations or irregularities can be identified, indicating potential counterfeiting.

Delamination occurs when different layers within a semiconductor package separate. Through C-SAM, cracks, voids, or delamination between the die and die paddle can be detected, indicating potential repackaging or improper assembly, or handling or storage issues. These delamination problems are often found in counterfeit devices that have undergone improper handling or rework, particularly with recycled parts from printed circuit boards (PCBs).

Prosemi's Commitment to Authentication and Quality Assurance

Prosemi's acquisition of a high-end C-SAM machine and extensive expertise represents a significant advancement in authenticating electronic components and ensuring top-quality assurance. The company's commitment to unique value propositions and innovative approaches have been recognized with the prestigious Manufacturing Technology award that Prosemi recently received at the SBR (Singapore Business Review) National Business Awards, recognizing its exceptional in-house electrical testing solutions.

Combining the C-SAM tool with the addition of IDEA-STD-1010, and leveraging other cutting-edge equipment like Scanning Electron Microscope, Fourier Transform Infrared Spectroscopy, electrical functional, and JTAG boundary scanning test solutions, Prosemi confidently positions itself as a leader in driving advancements and shaping the future of testing methodologies and solidifies its prominent standing within the industry.

Are you worried about the authenticity of electronic components? Get in touch with Prosemi today.

Prosemi has built a reputation among the world's largest CMs and OEMs for testing electronic components and providing baking, tape and reel, and IC programming services. Prosemi's world-class services are driven by their commitment to quality, extensive industry experience and exceptional technical capabilities.

Learn more about Prosemi's quality program and view current certifications here.