Energy conservation has become an important trend to achieve the goal of net zero emissions in 2050, and companies are all actively measuring their energy consumption. A power meter is the most basic measurement tool, but the power meter currently used by industries is too costly. The AI power sensor developed by the Green Energy & Environment Research Laboratories (GEL), Industrial Technology Research Institute is the size of your thumb, and can be integrated with micro energy management system (μEMS), cloud energy management, or industrial control system for visualized energy analysis. This will significantly reduce the cost and time of implementation, and provides a solution for rapidly revealing the power consumption of factories and office buildings.

AI Power Sensor Accuracy Reaches 99%

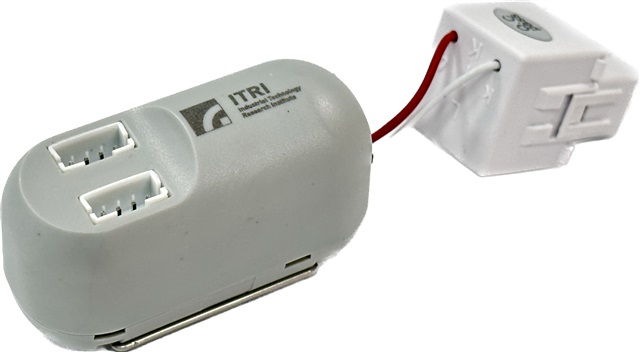

With the support of the Bureau of Energy, Ministry of Economic Affairs, the AI power sensor was developed by a 20-person team formed by engineers Ko-Ying Tseng, Bo-Yin Chu, and Hao-Ting Chao at the Sensor Monitoring Laboratory, Smart Energy Conservation System Technology Division, GEL, and includes a non-invasive power sensor and embedded AI analyzer. It obtains the electricity consumption information of multiple circuits using a non-invasive method similar to a stethoscope used by doctors. It is easy to install, low cost, and was measured by the National Measurement Laboratory (NML) to have an accuracy reaching 99%. This can be expected to increase the willingness of small and medium enterprises to implement an energy management system.

After over two years of R&D, the AI power sensor, also called power tab, despite being the size of your thumb, is able to remotely monitor power supply by tabbing it on power cables. The AI power sensor provides information similar to a conventional electricity meter, and helps companies accurately monitor the power consumption of their factories and offices. Ko-Ying Tseng shared that companies immediately saw the advantages of being easy to install and relatively low cost when the team began promoting the product, and it even attracted major power supply manufacturer Sea Sonic Electronics Co., Ltd. to engage in technology transfer, establishing the subsidiary "Sea Sonic Energy Co., Ltd." to focus on the energy measurement applications market.

Obtains electricity consumption information of multiple circuits using a non-invasive method similar to a stethoscope used by doctors, and is easy to install and low cost

AI Power Sensor that Punches Above its Weight

Bo-Yin Chu shared that companies in the Philippines, Thailand, and Japan have contacted them since they began promoting the product, which has already been installed by Far EasTone Telecommunications, Taipei Metro, and Nanya Plastics. Installation of the AI power sensor does not require power to be cutted off, and it is able to disclose energy details faster than typical electricity meters. The product can be applied in equipment failure prediction, and Nanya Plastics found equipment operating abnormally after installing the product.

"The greatest advantage is its high cost-performance ratio" said Ko-Ying Tseng. The average cost for installing an electricity meter is nearly NT$20,000. Meanwhile, the AI power sensor has complete functions and is extremely competitive compared to conventional electricity meters in terms of installation, effectively lowering the cost of hardware equipment and installation for electricity measurement. Higher return on investment (ROI) is the greatest advantage it provides to companies and system integrators.

AI power sensor effectively lowers the cost of hardware equipment and installation for electricity measurement and increases ROI

The GEL Hopes the TIE Award will Increase Exposure

The AI power sensor developed by the GEL was recognized with the TIE Award during Taiwan Innotech Expo this year, and will be displayed in the Future Tech Pavilion. Bo-Yin Chu pointed out that they hope to increase the technology's exposure through the TIE Award, because the AI power sensor is able to obtain electricity information through contactless installation, and rapidly reveal electricity consumption for energy management. He believes that the product will become popular worldwide once it gains exposure.

Ko-Ying Tseng stressed that customers will be able to directly operate the AI power sensor during the expo, and they prepared electrical equipment, such as hair dryers, for customers to operate the product, which intuitively displays electricity consumption in each stage. Going forward, they plan to integrate the technology with different applications beyond the energy measurement market, such as electrical safety, monitoring power cable temperature to prevent the risk of a fire accident; equipment diagnostics, monitoring abnormal states and providing early warning. This technology can become an irreplaceable first step to improving energy efficiency for net zero emissions.