According to DIGITIMES Research, influenced by the call for net-zero carbon emissions and increasing labor shortages, the cold chain/logistics industry is moving towards smart, highly efficient, and low-carbon solutions.

IoT technology is a crucial component in achieving these three primary goals. The concept of the Physical Internet (PI) makes its debut in Taiwan at this exhibition, highlighting temperature and humidity monitoring, carbon reduction, automated warehousing, and fleet management solutions.

Companies including Fox-Tech, Brocere Technology, Flutai, CiLS, Hai Robotics, OmniEyes and Eupfin Technology have all showcased their latest technologies and products at the shows.

Introduction

The Taipei International Logistics and IoT Exhibition 2023 and Taipei International Cold Chain Technology Exhibition 2023 were jointly held from August 23 to 26, with more than one hundred cold chain and logistics operators participating in the events. According to DIGITIMES Research, influenced by the call for net-zero carbon emissions and increasing labor shortages, the cold chain/logistics industry is moving towards smart, highly efficient, and low-carbon solutions.

IoT technology is a crucial component in achieving these three primary goals. The concept of the Physical Internet (PI) makes its debut in Taiwan at this exhibition, highlighting temperature and humidity monitoring, carbon reduction, automated warehousing, and fleet management solutions.

Fox-Tech and Brocere Technology showcased customized IoT solutions for temperature and humidity monitoring, with more censoring functionalities like carbon dioxide concentration and air quality detection, to be incorporated into related solutions per customer needs.

Flutai offers comprehensive planning for cold chain logistics warehousing and vehicle refrigeration equipment, including dual-power refrigeration machines that run on engine or battery power, reducing carbon emissions from logistics transportation.

Coretronic Intelligent Logistics (CiLS) is one of the two Taiwanese exhibitors showcasing autonomous mobile robot (AMR) solutions (the other being FARobot). They present self-developed AMR forklifts and handling vehicles and the iMEC intelligent management system, which offers warehousing operators smart management solutions.

Hai Robotics introduces the world's first cold storage container-type warehousing robot that can operate safely in temperatures as low as -25?C. Geek+ presents goods-to-person picking robots with smart sorting workstations, enhancing warehouse picking efficiency.

OmniEyes, with AI edge computing technology at its core, uses image recognition technology to monitor fleet drivers' behavior, helping improve driver safety and reduce improper driving behavior.

Eupfin Technology exhibited two major solutions for fleet management and transportation management systems, covering various application scenarios from driver behavior and vehicle status to cargo control and transportation cost management and providing comprehensive fleet management system services for logistics and fleet management operators.

Concept of PI

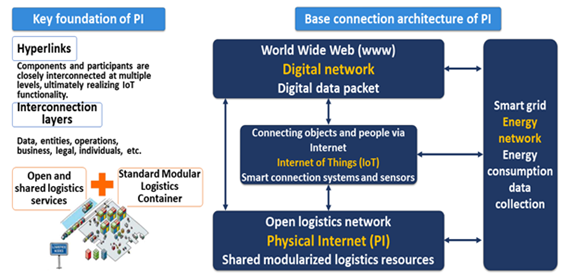

Table 1: Key foundation and base connection architecture of PI

Source: DIGITIMES Research, September 2023

As the logistics industry faces labor shortages, cost reduction, carbon reduction demands, and regionalization of the supply chain, the PI concept has become one of the solutions widely discussed for digital transformation in logistics in advanced countries like Europe, the US, and Japan.

PI is a concept that transforms the operations of logistics players, drawing inspiration from the Internet. It converts data transmission into physical logistics transport processes, creating a network that integrates global logistics systems. The PI concept advocates using standardized modular and shared logistics resources to achieve more efficient, environmentally friendly, sustainable transportation and logistics systems.

Georgia Institute of Technology in the US emphasizes that the key to building PI lies in hyperconnectivity and the interconnection layer. Hyperconnectivity refers to the close interconnection of various components (warehouses, trucks, and containers) and participants (distribution, management, and business personnel) on multiple layers, ultimately creating a network where everything is connected. The interconnection layer encompasses various aspects related to logistics, including data, physical elements, operations, business, legal, and personal factors.

IoT technology has become an essential tool for implementing PI, as it can connect data from various logistics nodes and the supply chain. An open logistics platform allows the sharing of logistics resources, such as warehouses, trucks, containers, and shelves, to form a more efficient, sustainable, scalable, and agile logistics system for related supply chains.

In response to the need for carbon reduction, energy consumption information can be integrated into the PI framework through the energy monitoring system to build a low-carbon logistics system.

The Alliance for Logistics Innovation through Collaboration in Europe (ALICE) has proposed a blueprint for the European PI construction to replace traditional logistics models by 2030. The plan aims to create a standardized, intelligent European logistics network. It is expected to be fully operational by 2040.

Table 2: Cold chain and logistics industries demand and solutions

Source: DIGITIMES Research, September 2023

According to DIGITIMES Research, with the aging population and labor force transformation, the high-risk working environment, and long working hours in cold storage and logistics, the cold chain/logistics industry faces challenges in recruiting workers and dealing with labor shortages. Additionally, as the cold chain/logistics transportation industry falls under the high carbon emission production category, it is transitioning towards smart, efficient, and low-carbon solutions in line with the global trend of achieving net-zero carbon emissions.

Demand for refrigerated and frozen transportation has become more diverse and quality-focused due to emerging fresh e-commerce, transforming convenience stores/supermarkets into fresh food outlets, direct sales of agricultural products, O2O (online to offline) operations, and transportation of medical vaccines. Relevant organizations have also proposed standards and regulations for cold chain logistics, such as the Cold Chain Industry Standard (CCIS) for the food sector and the new ISO 23412 international home delivery standard. The pharmaceutical industry has the PIC/S GDP (Good Distribution Practice) for drugs.

While these standards have not yet become legal regulations, businesses in the cold chain industry can develop smart management applications based on these standards, including tracking data such as cargo conditions, temperature control, and transportation processes. Related solutions include IoT temperature and humidity monitoring, cold storage preservation technology, energy-saving systems, and green transportation.

Companies like Advantech, Brocere, Elite Semiconductor Microelectronics Technology (ESMT) and Fox-Tech showcased temperature and humidity monitoring solutions. Meanwhile, Taro & TYC exhibited various cold storage containers, and Carrier highlighted integrated display and cabinet solutions for refrigeration and cold storage. Flutai presented solutions for refrigerated and frozen vehicles and cold storage systems. Hotai Development and Panasonic Taiwan exhibited various air conditioning and cold chain equipment.

Logistics operators focus on automation and efficiency solutions, including unmanned warehouse systems, automated handling/sorting equipment, smart fleet management systems, and intelligent warehouse planning solutions.

Other companies, including Coretronic Intelligent Logistics (CiLS), Geek+, Hai Robotics, Vicstore, Winsonic Mechatronics and 3-Bridge Autotech, highlighted intelligent warehouse and automated handling/sorting solutions. G4 Technology and Sato Taiwan offered labeling and RFID reading system services. Eupfin Technology and OmniEyes showcased fleet management systems.

Company showcases

Fox-Tech and Brocere

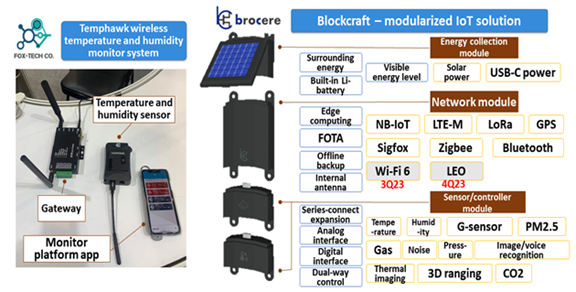

Table 3: Product showcases by Fox-Tech and Brocere

*Note: FOTA stands for firmware over the air.

Source: Fox-Tech and Brocere; compiled by DIGITIMES Research, September 2023

Fox-Tech has come out with an integrated IoT solution named Temphawk, which does not require a power plug. It can automatically monitor and record real-time data such as temperature and humidity to improve operational processes.

The Temphawk is packed with temperature, humidity, carbon dioxide (CO2), light intensity, and soil electrical conductivity (EC) sensors. The wireless temperature and humidity sensors use Zigfox low power wide area network (LPWAN) to transmit the collected data to the cloud. Zigfox offers advantages like long-range coverage, low power consumption, and cost-effectiveness, making the Temphawk suitable for monitoring environmental temperature and humidity over broad areas.

The sensors have an IP68 waterproof and dustproof rating, making them suitable for harsh environments, including outdoors, low temperature, and humid conditions. They are powered by button-cell lithium batteries with a battery life of up to 10 years, eliminating the need for additional wiring or frequent recharging.

The temperature measurement of the sensors ranges from -40?C to 125?C, and they automatically upload data every 10 minutes. Users can remotely monitor temperature and humidity conditions in the field in real-time through a web platform or a mobile app and receive alert notifications in case of anomalies.

Fox-Tech can also provide customized remote control solutions for agriculture, food processing, cold chain logistics, and food and beverage industry applications.

The Temphawk solutions have reached markets in 26 countries worldwide, with customers including Amazon Japan, Hotai Development, Fwusow Industry and RD&D Cold Logistics.

Brocere provides customized IoT solutions. It has developed a building-block type modularized IoT Blockcraft sensor, which allows customers to flexibly select and connect various sensing modules in series, such as temperature, humidity, fine suspended particles (PM2.5), positioning, vibration, and face/voice recognition.

The Blockcraft has built-in GPS and G-sensors for real-time tracking and data upload to a logistics and operation monitoring platform. It can be paired with communication solutions such as NB-IoT, LTE-M, LoRa, Sigfox, and low Earth orbit satellites to meet most wireless sensing and remote monitoring needs. It also offers easy installation, calibration, and maintenance.

The Blockcraft has an IP67 waterproof and dustproof rating, making it suitable for outdoor use and other harsh environments.

The built-in battery can last over a year and be charged using a type-C cable from a mobile power source. Alternatively, a solar module can be added to make the sensor self-sustaining, promoting environmental sustainability and reducing maintenance costs.

The Flutai Group

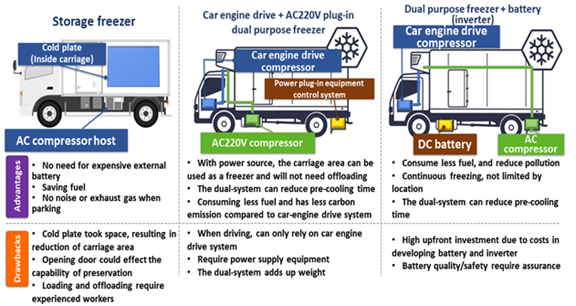

Table 4: Product showcases by Flutai Group

Source: Flutai Group; compiled by DIGITIMES Research, September 2023

The Flutai Group offers one-stop cold chain services, including refrigeration units and vehicles, ground handling vehicle/equipment, and diagnosis and planning for integrating cold chain services (such as cold chain warehousing planning). The group holds over 80% of Taiwan's airport ground-handling vehicle market.

Taiwan's government has set a target to achieve net-zero carbon emissions by 2050 and has introduced related subsidies to encourage businesses to embrace smart and low-carbon solutions.

The transportation industry is the third-largest contributor to carbon emissions in Taiwan. The Taiwan Cold Chain Association has established an ESG Innovation Committee to assist its members in pursuing low-carbon initiatives and securing government support. The Flutai Group also provides low-carbon solutions for cold-chain transportation.

The carbon footprint of cold chain transportation includes carbon emissions from conventional diesel vehicles during transport and the electricity consumption required for cold chain operations. Traditional cold chain vehicles use the engine to power the refrigeration compressor, leading to increased carbon emissions when the engine remains running (during idling or loading/unloading). To reduce carbon emissions in the cold chain, relevant vehicles can transition to electric models or optimize the power source for refrigeration and freezing.

Cold storage refrigeration units with thermal storage plates installed inside the cargo compartment in a vehicle can be pre-cooled to the target temperature at night before delivery. The delivery products are transferred from the cold storage or freezer to the vehicle in the morning. This approach can significantly save on transportation fuel. However, it has drawbacks, such as reduced cargo capacity due to the space occupied by thermal storage plates and the impact of door opening and closing on the internal temperature, potentially affecting product quality.

The refrigerated vehicle with a cold storage refrigerator equipped with a cold storage plate in the carriage can plug in to pre-cool the car to the target temperature the night before delivery. Then, the goods are moved from the freezer or refrigerator to the vehicle for delivery in the morning, which can significantly save transportation fuel. However, the disadvantage is that the cold storage plate takes up space, which reduces the cargo capacity, and the number of opening and closing doors will affect the temperature inside the compartment, which can easily affect the quality of the goods.

Dual-purpose refrigeration units, powered by the vehicle's engine and an external power source, can synchronize operation when plugged in, speed up the refrigeration process, or rely solely on plug-in cooling to reduce exhaust emissions when starting the engine. Additionally, they can be plugged in at night to act as a refrigerated/freezer unit, maintaining product integrity and reducing the number of loading and unloading cycles.

Dual-purpose refrigerators with batteries and inverters can use battery power to drive the refrigerated unit when no external power supply is connected. The refrigerated unit can support vehicle facilities (such as gullwing doors) to serve as a mobile store when the vehicle is not running.

CiLS

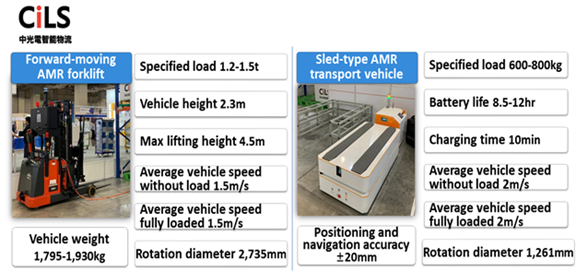

Table 5: Product showcases by CiLS

Source: CiLS; compiled by DIGITIMES Research, September 2023

CiLS, a subsidiary of Coretronic, introduces a highly integrated AMR (autonomous mobile robot) solution, including sled-type transport vehicles, AMR forklifts, trolley carts, and the iMEC intelligent management system. These solutions assist businesses in enhancing warehouse management efficiency and reducing the need for manual labor.

CiLS' highly integrated AMR solution links AMR with an intelligent management system. It offers seamless integration with ERP (enterprise resource planning) and MES (manufacturing execution system), allowing for comprehensive control of transport vehicles, peripheral equipment, environmental sensors, and the integration of information flow, financial flow, and logistics. This close integration of IT (information technology) and OT (operational technology) addresses issues like labor shortages, human error, and inefficient warehouse space utilization.

The AMR forklifts include tugger-type, pallet-style, forward-moving, and high-lift models. They use 3D SLAM (Simultaneous Localization and Mapping) for environmental positioning, enabling indoor and outdoor navigation, operation on uneven surfaces, and navigation without markers. Additionally, they utilize AI cameras for pallet and cargo recognition, location recognition, cargo height/width detection and obstacle identification.

The AMR transport vehicles consist of lift-type, roller-type, double-layer roller, heavy-duty roller, and sled-type models. They use 2D SLAM navigation and offer features like safety stops, elevator control, obstacle avoidance routing, and the ability to move between floors. They are equipped with AI cameras that can identify and pick up pallets, overcoming the limitations of traditional transport vehicles that can only carry and deliver products on fixed-type warehouse shelves.

AMR solutions can autonomously plan operation routes and task schedules based on missions. They have obstacle-avoidance sensing capabilities to ensure the safety of goods and on-site personnel during transport.

Implementing CiLS' AMR solutions does not require facility modifications and can be introduced zone by zone. This gradual approach improves warehouse automation levels, space utilization efficiency, and accuracy while reducing labor burdens and the risk of human error, resulting in cost savings and enhanced operational efficiency for businesses.

Hai Robotics

Table 6: Product showcases by Hai Robotics

Source: Hai Robotics; compiled by DIGITIMES Research, September 2023

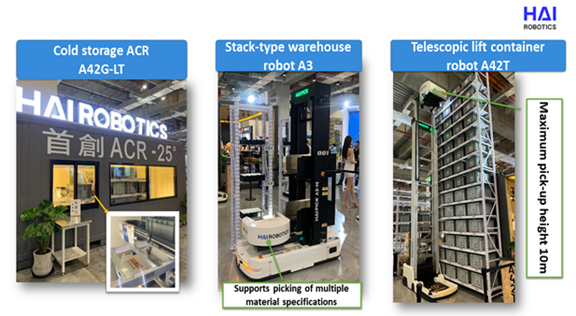

China-based Hai Robotics primarily focuses on researching and designing autonomous case-handling robot (ACR) systems for warehousing. The company independently develops everything from the robot to the underlying positioning algorithms, control systems, robot scheduling, and intelligent warehouse management systems, amassing over 1,500 global patents.

During the exhibition, Hai Robotics showcased the industry's first cold storage ACR (model A42G-LT). It comes equipped with sensors, batteries, lubricants, and control systems capable of operating safely in -25?C low-temperature environments.

The A42G-LT features a heat exchange system that dissipates the robot's heat to prevent frost buildup.

The A42G-LT can be applied to food, pharmaceutical, and electronics industries in cold storage. It assists businesses in improving cold storage efficiency, accuracy, and safety while reducing the need for prolonged human labor in low-temperature environments.

Hai Robotics is a pioneering and leading provider of ACR systems. Its Haipick system has evolved to its fourth generation and was among the earliest systems developed and deployed for commercial use. It enables warehouse automation management, offering intelligent handling, picking, sorting, and customization.

The company's stack-type warehouse robot, A3, is suitable for various types of pallets and layer-stacked materials, as well as vehicle cartridges, making it ideal for manufacturing line-side and production-line transport.

The ACR series is compatible with various material specifications and height adjustments, meeting the complete needs of the entire production line (warehousing + transport) for raw materials, semi-finished products, line-side operations, production-line transportation, and finished goods.

The telescopic lift container robot, A42T, can reach heights of up to 10 meters, which is currently the highest in the industry. It significantly enhances vertical space utilization in warehousing and includes multiple storage back baskets, allowing it to carry up to 9 containers simultaneously, thereby improving picking efficiency.

Geek+

Table 7: Product showcases by Geek+

Source: Geek+; compiled by DIGITIMES Research, September 2023

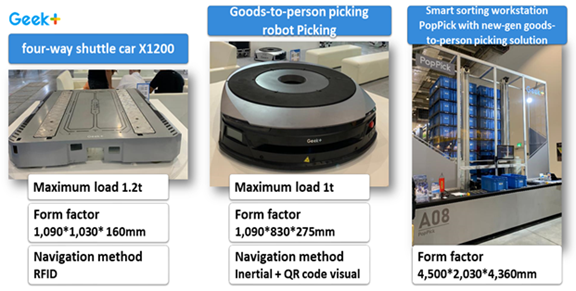

China-based Geek+ specializes in developing intelligent logistics AI robots and provides services in over 30 countries and regions worldwide. The company claims it has held the global top position in the AMR market for three consecutive years. Its clientele includes primary players in the fashion, e-commerce, retail, logistics, pharmaceuticals, electronics, automotive, and cosmetics industries, with customers like Decathlon, Gigabyte Technology and PChome.

Geek+ possesses an in-house developed AMR/AGV (automated guided vehicle) robot platform, which includes shuttle cars, goods-to-person picking robots, and the PopPick intelligent warehousing station. It can also provide customized warehousing management solutions.

The four-way shuttle car is an access robot that can move horizontally in four directions along a track inside vertical racks. Its narrow body design saves approximately 40% in width compared to traditional forklifts, improving storage efficiency.

The goods-to-person picking solution employs the P-series goods-to-person robot, which transports inventory shelves and pallets to picking stations. The P-series robots disrupt the traditional method of people searching for items, reducing the labor intensity for pickers, decreasing the time spent by personnel moving to find things, and increasing accuracy, resulting in more than a threefold efficiency improvement.

The goods-to-person picking robot transfers movable shelves to the PopPick sorting workstation, completing tasks such as shelving, picking, restocking, sorting, and inventory checking. Using AI algorithms to predict orders, the robot can perform sorting during the night or idle periods without human intervention, eliminating the need for personnel and facilitating cargo exchange between different shelves. It organizes outgoing products and moves highly related items to the same brackets, optimizing operational efficiency.

The PopPick workstation is designed based on ergonomics. It features four picking positions that can flexibly switch between single and double-person modes, resulting in a four-fold increase in picking efficiency.

OmniEyes

Table 8: Product showcases by OmniEyes

Source: OmniEyes; compiled by DIGITIMES Research, September 2023

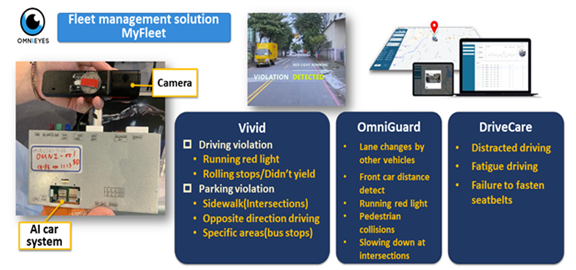

OmniEyes offers a fleet management solution called MyFleet that primarily utilizes edge AI computing and image recognition technology. MyFleet combines image data with other sensing data to perform driver behavior analysis, vehicle condition monitoring, and fleet management, assisting businesses in improving fleet safety and efficiency. MyFleet's main AI computing functions include Vivid, OmniGuard, and DriveCare.

Vivid can instantly detect and warn against driver violations such as running red lights, driving in the wrong direction, rolling stops, and illegal parking in specific areas or on pedestrian crossings. All violations are immediately alerted through image warnings, enhancing safety for both drivers and pedestrians.

OmniGuard integrates an advanced driver assistance system (ADAS) with critical driver behavior detection from OmniEyes, issuing warnings to alert drivers about their surroundings, including lane changes by other vehicles, pedestrian collisions, and slowing down at intersections.

DriveCare offers driver behavior analysis, including distracted driving, fatigue, and failure to fasten seatbelts, providing instant reminders to help drivers avoid road hazards resulting from distraction and fatigue.

Users can choose an AI driving recorder or AI car camera as hardware. AI car cameras can use USB/RS232/Bluetooth to connect various sensors, including temperature sensors, altimeters, card readers, and tire pressure sensors.

MyFleet's fleet management platform employs edge computing technology to perform real-time AI analysis on cars, with videos of relevant accidents uploaded to the cloud for storage and analysis reports. MyFleet can be integrated with customers' existing management systems through an application programming interface (API).

Eupfin

Table 9: Product showcases by Eupfin

Source: Eupfin; compiled by DIGITIMES Research, September 2023

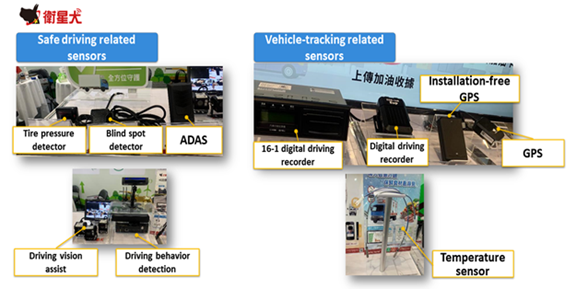

Eupfin Technology was founded in 2004 and introduced its branded fleet management solution, Satellite Hound, in 2008. The company is dedicated to researching and developing intelligent transportation management and driver safety systems, assisting fleet operators toward digital transformation, energy conservation, and carbon reduction, and providing diverse fleet management solutions for different fleets. Over 90% of tour bus operators in Taiwan use the Satellite Hound vehicle management system.

Eupfin has subsidiaries in Vietnam, Malaysia, Thailand, and Indonesia, offering fleet management services to over 100,000 vehicles globally. Its customers include logistics operators, taxi fleets, and emergency services operators.

Eupfin's solutions can be categorized into two primary systems: fleet management and transportation management.

The essential features of the fleet management system include real-time GPS vehicle positioning and historical route tracking, instant detection and warnings for driver violations, operational analysis reports, optimal route planning, and cloud-based instant replay of event footage. These features help businesses enhance fleet safety, control fleet costs, and improve vehicle utilization.

The transportation management system performs order management and tracking, customer profile buildups and maintenance, online rapid dispatch, and transportation progress tracking.