As the final step in the production process, inspection is of critical importance to the manufacturing industry. Manufacturers generally allot adequate staff resources to perform inspection for the purpose of safeguarding product quality. However, there is a limit to what people can do and human visual inspection may be error-prone.

To address the issue, LEDA Technology adopted ADLINK's machine vision system and built a smart inspection solution for use as part of a contact lens manufacturing process. According to LEDA Technology CEO Che-Hsian Huang, aside from quickly catching product defects through machine vision-based inspection, the solution can also collect data from individual inspection devices and conduct AI training to keep strengthening the inspection performance.

Starting out as a developer of image processing technologies, LEDA has been expanding into artificial intelligence (AI) technology research as smartization becomes a trend in manufacturing in recent years. It is working on solutions that capture and feed image data to the system to do further processing, the result of which then serves as the basis for making process improvements. LEDA currently focuses on technology development and system application for the manufacturing industry, including defect inspection of LED, metal work pieces and contact lenses. In particular, its solution used in the contact lens manufacturing process is a benchmark representative of LEDA's incredible achievement in AI-enabled machine vision.

The CEO said that consumer demand for contact lenses is on the rise for style and convenience reasons. To keep up with the increasing demand, manufacturers need to produce them at a rapid rate. As contact lenses are made from transparent materials, making machine vision-based inspection very challenging, inspection has generally been performed by humans. Furthermore, manufacturers conduct 100% full inspection on contact lenses as opposed to most other products for which sampling inspection is more common. Due to production in a large quantity and at a rapid rate in addition to 100% full inspection, inspectors have to visually check about 4,000 small contact lenses a day, which causes the rates of false discovery and missed detection to remain high. LEDA's solution can improve inspection performance for manufacturers with help from ADLINK's hardware platform and professional technical support.

According to LEDA CTO Si-Syuan Huang, to improve manufacturing system performance, instabilities on the production line need to be kept to a minimum so that data can be steadily generated and accurately tracked and then used to calibrate the production process for maximum benefits. Human visual inspection is the main cause of instability in the current manufacturing process, especially in the case of contact lens production lines where mass-quantity inspection is conducted. In view of this, LEDA first introduced a machine vision system to replace human visual inspection and then used the digital data gathered by the system to develop AI algorithms, thereby building a smart manufacturing system from the bottom up.

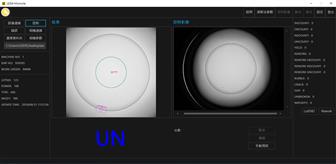

LEDA's AI-enabled machine vision inspection system for contact lenses built on top of ADLINK's EOS-i6000 vision system features the Intel Movidius accelerator, the 9th generation Intel Core i7 processor and support for Intel OpenVINO. The system comes preloaded with a validated AI development platform so it can reduce the efforts needed for testing and integration, thereby significantly shortening the development cycle. EOS-i6000 is optimized for machine vision applications and fully supports a wide variety of deep learning applications. With proven track records in energy consumption, heat dissipation and compatibility, the platform is an ideal edge device complementing a smart manufacturing system.

The CTO indicated that due to the complexity of production line configurations and the diversity of factory equipment, when setting up machine vision systems for customers, system providers often have to test all kinds of industrial cameras with different specs and features. If the test results are not as good as expected, the engineering team will have to study the cameras under test again until the system performance meets expectation. ADLINK's EOS-i6000 comes with a built-in GigE camera interface and image capture app along with its proprietary ADLINK Edge development kit, allowing quick and easy connection to other equipment and cloud, so that the LEDA team can focus on algorithm development and shorten the time it takes to get the system up and running.

With ADLINK's help, LEDA successfully developed the AI-enabled machine vision inspection system for contact lenses, which allows users to configure the standard on defect detection and precisely screens products based on the user-defined standard. It solved the problem of high false discovery and missed detection rates with human visual inspection. The system can also keep inspection logs which serve as product traceability records for customer reference. In addition to precise product inspection, LEDA's solution also leverages EOS-i6000's features to build deep learning systems for customers.

The precision of deep learning hinges not only on the algorithm but more importantly on the data. Only with a sufficient amount of high-quality data can the model training results be accurate. However, due to manufacturing systems' limited capabilities, AI system providers generally have to wait until a certain amount data has been accumulated from the manufacturing process and then send the data back to do training. The back-and-forth process is time-consuming and it takes a long time to get the system up and running. To address this issue, LEDA makes use of EOS-i6000's strength to allow its machine vision system to collect data on the production line and tap into the customer's servers to perform deep training. According to the CEO, in its early development stage, LEDA's AI-enabled machine vision inspection system for contact lenses first learned from humans by having the AI system operate alongside experienced human inspectors who would correct and mark the mistakes the AI system made. The approach enabled the system to develop the rules and logics of the deep learning algorithm while accumulating adequate data for the system to keep improving its precision.

The AI-enabled machine vision inspection system for contact lenses LEDA built is now in operation on its customer's production line. LEDA was able to get the system up and running within a short period time. The CEO attributed the success to ADLINK's full support. He pointed out that although there is a wide selection of AI-enabled visual hardware platforms on the market, very few vendors have the expertise in both AI and machine vision. With years of experience in machine vision and a team of AI experts, ADLINK gave LEDA its full support throughout their collaboration. This allowed LEDA to significantly cut down the development time and cost. Going forward, the two firms will continue to engage in close partnership, crafting tailor-made smart systems suited to customer needs.

Explore the contact lens inspection solutions, please visit the page.

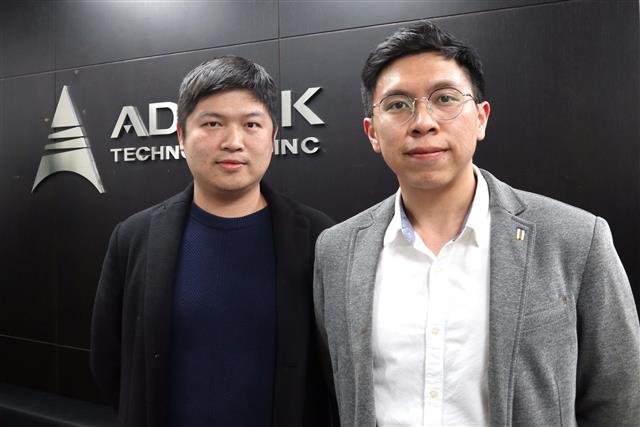

LEDA Technology Che-Hsian Huang (left) and CTO Si-Syuan Huang (right) both point out that AI-enabled machine vision not only ensures stable product quality but also aggregates data for use in process improvement

LEDA Technology adopted ADLINK's machine vision system and built a smart inspection solution for use as part of a contact lens manufacturing process

DIGITIMES' editorial team was not involved in the creation or production of this content. Companies looking to contribute commercial news or press releases are welcome to contact us.