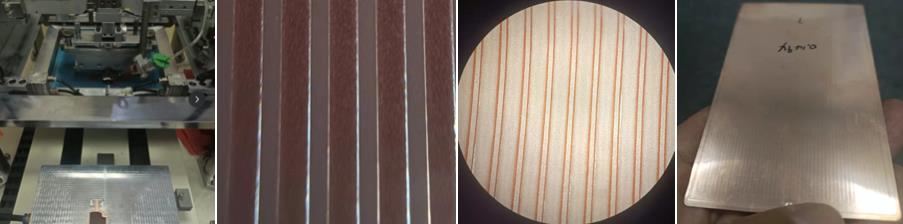

Suzhou-based professional thermal module maker, Jieqiao Electronics Technology, announces it has reached a formal technology license agreement with NeoGene Tech to adopt MagicWick-Inside Technology Platform for designing and fabricating ultra-thin vapor chamber products. By adopting such novel technology, Jieqiao is able to build Print Wick Structuring (PWS) production line in their Kunshan plant for making a series of ultra-thin vapor chamber devices with thickness ranging from 0.3max to 0.2max.

NeoGene Tech, a vapor chamber technology platform and materials provider in Guangzhou, China has been devoted to revolutionizing the way of designing and fabricating ultra-thin vapor chambers devices for 5G mobile computing applications for years. NeoGene Tech's MagicWick-Inside Technology Platform along with PWS approach categorizes the ultra-thin vapor chamber technology into three levels. The technology license program will be enabling Jieqiao to produce high-quality ultra-thin vapor chamber products by the technology from Level 1 to Level 3.

"Although the thickness of current ultra-thin vapor chamber at above 0.3max can be made by traditional copper mesh wick structuring technology, PWS technology has an obvious advantage to make the VC devices at higher performance and higher production yield rate. Furthermore, most smartphone brands are pursuing thinner (<0.25max) and bigger (>5000mm2) vapor chamber devices technology for fitting new thermal management needs in their new product models. The traditional copper mesh approach will be encountering more difficult issues once the device thickness is lower than 0.25max, not to mention the device area is bigger than 5000mm2. The space for wick structure and vapor channel is too narrowed to deploy in production. As a result, the PWS approach is the best solution for vapor chamber makers to overcome such problem and it is also a very economical way for mass production," according to Jeffrey Chen, CEO of NeoGene Tech.

"Thanks to MagicWick-Inside Platform and PWS approach, it empowers Jieqiao to quickly move into mass production in high performance and high-end vapor chamber devices market. Our flow channel design capability and PWS production line for MagicWick-Inside VC will be ready for mass production in Q2, 2022. By adopting Level-1 to Level-3 technologies, the high-performance vapor chamber with thickness at over 0.3mm or the vapor chamber at under 0.25max and size at over 5000mm2 can be delivered to market accordingly. The production of MagicWick-Inside VC with a large area and a thickness of only 0.22max will be our strength," said Ricky Liu, Chairman and CEO of Jieqiao.

"Jieqiao is the first local thermal module company in China adopting PWS solution for ultra-thin vapor chamber fabrication. We are more than happy to have Jiequao adopt MagicWick-Inside Platform and PWS approach. So far in great China territory, we already have Taiwan-based and China local-based vapor chamber makers licensed our patented technology. The PWS approach has also been adopted in vapor chamber production lines. We are seeing that more and more vapor chamber makers will join and be benefited from this platform and technology soon. NeoGene Tech's mission is to continuously work with 5G smartphone brands to promote and refine the design and fabrication of ultra-thin vapor chamber devices in thermal management technology," said Jeffrey Chen, CEO of NeoGene Tech.

Jieqiao reaches MagicWick-Inside Platform license agreement with NeoGene Tech