Monitors are seen as the last mile for many smart systems. However, as application fields increase in variety, this last mile must also provide more functional specifications so that users can have an experience that is both convenient and eye-opening. The DP-173X-UHD industrial touch monitor recently launched by Atemitech Corporation, a key subsidiary of Getac Holdings Corp, provides industrial users with a stable, highly efficient human-machine user experience in its products through MiniLED backlight modules, unique composite materials developed by Atemitech, and a number of unique designs.

More flexible monitor design goes beyond the existing solutions on the market

Atemitech Corporation's DP-173X-UHD industrial touch monitor uses a MiniLED backlight source. Past MiniLED LCMs would integrate the timing controller chip and the LED driver chip into the LCM control board. But since this method would limit the selectable brands of timing controller chips, Atemitech Corporation proposed two other circuit structures, each of which going beyond the limitations imposed by existing timing controller chip solutions on the market.

Atemitech's first solution (hardware) is to insert a bridge between the output interface of the main board and the input interface of the panel. This bridge integrates the local dimming ASIC and the MiniLED driver chip. After the image signal undergoes local brightness calculation by the local dimming control chip for each frame, brightness control of the local backlight is completed through the MiniLED driver chip. The second solution is to connect the MCU bridge to a USB interface. The calculation of local dimming is performed by special software at the backend of the operation system. After the calculation, local grayscale is sent by the MCU to command the MiniLED driver chip to complete the operation. Using either the first or second solution, the MiniLED driver chip used in the DP-173X-UHD supports 576 local dimming zones.

In addition, highlighting the 100,000:1 ultra-high contrast ratio of the DP-173X-UHD's MiniLED HDR, the projected capacitive (PCAP) touchscreen, and full-black display after optical bonding, the ink black color must be adjusted for consistency with the chromatic aberration of the monitor, which also allows the screen area of the DP-173X-UHD to display Integrated Black Panel (IBP) effects in the borders when in a dark state.

Impact resistant, light-weight, and flexible shape—Atemitech's unique composite material offers obvious advantages

In terms of the panel, the cover lens of the DP-173X-UHD adopts Atemitech's unique composite material. At present, most cover lenses on the market are made of glass or plastic. Atemitech's unique composite materials and manufacturing process boast impact resistance, light weight, and shape flexibility (the material can be curved), which are far superior to those of glass. The stress of the composite sheet during extrusion can be released by controlling the temperature and flow rate of the process, which reduces rainbow pattern effects. The composite sheet produced by extrusion molding with coating technology has the most obvious advantages among all the cover lens solutions using different materials, making it suitable for vehicle-mounted monitors, industrial controls, military use, and other outdoor scenarios where safety and practicality are of paramount importance.

The unique composite front panel used in the DP-173X-UHD can provide customers with a complete solution. Atemitech optimized the surface hardness, anti-glare/reflection, anti-fingerprinting, and other optical properties of the composite sheet through its coating technology. In addition, it can also adjust the transmittance and ink colors of the lens according to design requirements, which gives the display a "true black" effect, allowing users to feel the high levels of visual texture in the display. In addition, the introduction of hot pressing makes Atemitech capable of producing curved front panels. Atemitech provides complete solutions in the processes of bonding unique composite materials and touch touchscreens and in the optical bonding of MiniLED panels. It possesses the ability to satisfy end-client design requirements for cover lenses, while also having the ability to monitor the entire process with efficacy in real time, thus ensuring product quality.

Atemitech Corporation's LumiBond sunlight readable monitor solution provides the most stable visual experience

As for the touch screen, both the touch screen and control board of the DP-173X-UHD can be customized according to customer needs. This product adopts 17.3" projected capacitive touch technology. In addition, the DP-173X-UHD has incorporated Atemitech's LumiBond solution.

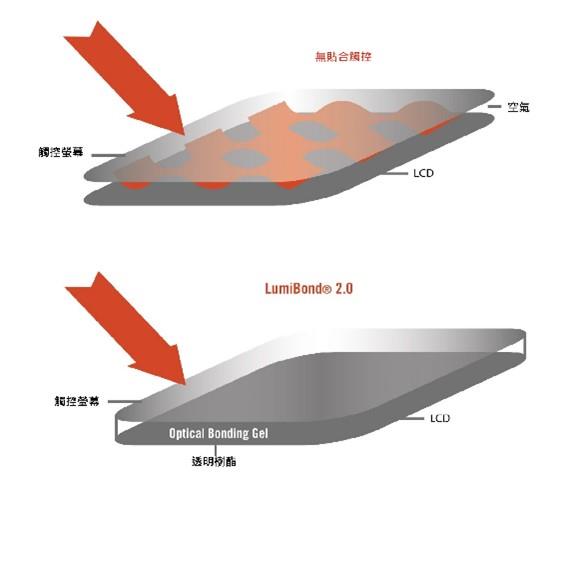

LumiBond is a technology solution developed by Atemitech that is designed to improve the usability of touch screens; it has been applied to touch monitors in various products, including the DP-173X-UHD. LumiBond maintains clear visibility of the screen even under strong ambient lighting, all without sacrificing brightness, contrast, and color saturation. The outstanding color display capability of this solution is mainly the result of two technologies: the first is Atemitech's exclusive low-power, high-brightness backlight module technology, which gives the UHD LCD display a brightness of up to 2000 nits (cd/m2) that can remain clearly visible even under direct sun lighting. The second technology eliminates the air gap between the LCD and touch screen, thereby greatly lowering visual interference and allowing more of the light generated by the backlight to emit, reducing the interference from ambient lighting.

LumiBond also enables the DP-173X-UHD with mode-switch for operating the display with gloves and in the rain (since water also has conductive properties).

In a low-temperature environment, humid air forms water droplets when it comes into contact with the relatively colder glass, and the droplets will be misinterpreted by the touch screen as fingertips. LumiBond can alter the sensitivity of the screen for operating in water, thereby reducing the possibility of malfunction. LumiBond also reduced the gap inside the display to maintain the temperature of the screen glass; this reduces the chance of cold air entering the display and allows the heat inside the device to be transferred to the touch screen surface, ensuring its normal operation.

In addition, LumiBond applies a transparent resin layer to eliminate condensation between the touch screen and LCD layer. At the same time, it enhances the strength of the LCD panel and the touch module assembly, so that it can withstand large collisions, vibrations, and falling, while also maintaining stable operations in a wide temperature range of -30°C-85°C, making it very suitable for outdoor systems.

With the popularization of smart systems, there are ever more functional requirements for touch monitors in systems operating in harsh environments, such as factory human-machine interface and process monitoring, vehicle mounting, automatic service machines, medical treatment, games, aerospace, energy, or oil extraction. Since stability, image rendering effects, and a convenient operation interface are all combined in the DP-173X-UHD, it can optimize both the user experience and the work efficiency of operators.

Atemitech holds to its rich OEM & ODM experience, solves usage pain points for its clients, continues to introduce high tech, and pursues development of new technologies; with its own process technology as its core capability, Atemitech generates high added-value through design, processing, and manufacturing, providing complete solutions for its OEM & ODM customers.

The Atemitech DP-173X-UHD industrial touch monitor.

Comparison of light emission modes of the MiniLED Touch Monitor and LED lightbar Monitor.

Comparison of LumiBond 2.0 Optical Bonding for Touch Displays and Non-Bonding.