Countries around the world are promoting renewable energy, for which solar power accounts for over half of green electricity. However, solar panels have a service life of less than 20 years, and can only be incinerated once they are scrapped; the CO2 generated has become a severe issue. California has even enacted strict laws to prohibit incineration. The solar panel recycling equipment developed by TSGC Technologies uses AI to break down solar panels into raw materials, so that they can be 100% recycled and reused.

TSGC Technologies is a spin-off of the National University of Tainan established with subsidies from the National Science and Technology Council in 2022. The company uses physical technologies to develop a solution with zero pollution and fully recycles solar panels. The co-founder Professor Yaw-Shyan Fu shared that TSGC Technologies is the first startup of the National University of Tainan in over 120 years. The company's goal is to accelerate the transition to solar PV through circular economy, and apply IoT, blockchain, and decentralized network technologies to integrate a carbon rights economy.

TSGC Technologies Uses Equipment to Take Apart Solar Panels for Recycling and Reuse

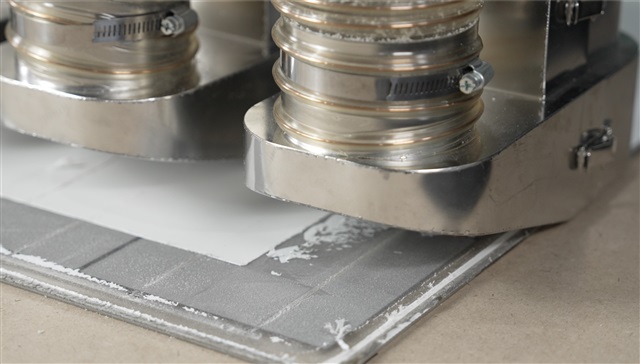

Prof. Fu pointed out that the team developed an equipment "PV Circulator," which uses blades for precise grinding when end-of-life solar panels are placed inside. The AI recognition system then sorts raw materials, including aluminum frame, junction box, backsheet materials, packaging materials, and silicone wafers. These materials are waste when they are mixed together, but have value when they are separated. The goal of TSGC Technologies is to create value through 100% recycling and reuse.

Precision grinding method using blades to remove materials

It is not easy to take apart an end-of-life solar panel. Prof. Fu pointed out that there are over 2,000 types of solar panels in Taiwan, and over 20,000 types in California. Each type is different, so the equipment uses AI for recognition and takes apart the solar panels. The parameters are then recorded in the cloud, including recycling rate and electricity consumption taking the solar panel apart, and are all converted into carbon emissions. The immutability of block chain is then utilized to provide a recycling history to the solar panel's owner to obtain a carbon reduction certificate, which may be converted into carbon rights in the future, using this to encourage companies to recycle their solar panels.

Using AI recognition for dismantling and providing a recycling history to solar panel owners

Countries Around the World are Searching for a Zero Pollution Solution for Solar Panels

Countries around the world are currently subsidizing solar panels. Prof. Fu pointed out that Europe, the United States, and Japan were the first to being using solar panels, and it led to severe pollution later on. Current solutions in the market, such as the hot knife method and tunnel thermal decomposition method of Japan's NPC, as well as the European Union's Full Recovery End-of-Life Photovoltaic (FRELP) all involve chemistry, heat, or burying.

California originally crushed and then incinerated solar panels, but enacted a strict law to prohibit incineration in 2021. Prof. Fu pointed out that the equipment of TSGC Technologies is able to recycle and reuse 99% of solar panels without using chemicals or incineration, and it is currently the only equipment in the world that complies with California's laws. Hence, the team is currently developing mass producing plan of the equipment in hopes of helping countries around the world achieve net zero emissions, with the ultimate goal of achieving 100% recycling and reuse.

TSGC Technologies Hopes to Market its Technology Worldwide Through the TIE Award

The solar panel recycling solution developed by TSGC Technologies was recognized with the TIE Award during Taiwan Innotech Expo this year, and will be displayed in the Future Tech Pavilion. Prof. Yaw-Shyan Fu pointed out that TSGC Technologies has extraordinary technologies, but it lacks a global marketing network and hopes to increase its international exposure through the TIE Award. Hence, the equipment and model displayed will provide a complete introduction of the solution for taking apart solar panels using physical technologies.

Transporting entire solar panels is very costly, and exceeds US$2 million for 500 MW. Prof. Yaw-Shyan Fu stressed that the head office of TSGC Technologies is located in the United States, and Taiwan is the production base. The company is currently discussing future cooperation with companies in California, and also has an opportunity to work with Belgium's Wallonia Export-Investment Agency. The company hopes that its next step will be to take action, directly transport the equipment to its destination, and begin taking apart solar panels, accelerating the energy transition of solar power.