Steel is a critical raw material for the wind industry. While steel makes up a quarter of the materials needed for onshore wind per MW, it jumps to a staggering 90% for offshore installations, dwarfing all other materials combined.

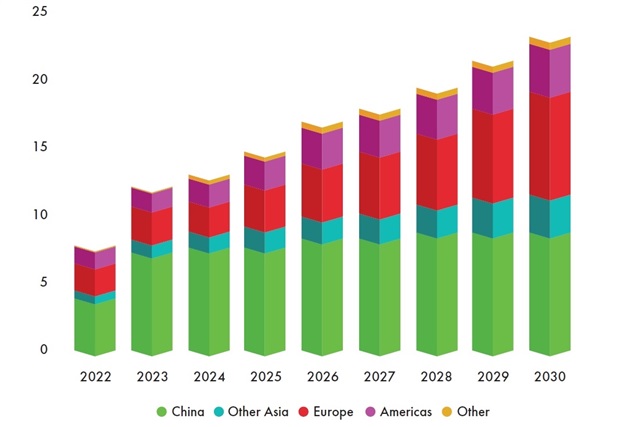

The wind energy sector is a major contributor to the growth in the demand for steel plate. Based on GWEC Market Intelligence's 2030 global wind market forecast, there is a potential for the demand to double by the end of the decade.

Modeled* steel plate consumption in the wind energy sector 2023-2030, Mt

Credit: CRU, GWEC. *Estimated steel needs of wind energy capacity forecast to be installed per year

Taiwan aims to cultivate 15GW of offshore wind power by 2035, anticipating a surge in steel demand to approximately 1.6-1.7 million tons.

Taiwan, characterized by elevated temperature, humidity, and a geological predisposition to typhoons and earthquakes, diverges in its approach to offshore wind infrastructure. Unlike Europe's monopile structures, Taiwan predominantly opts for jacket-type underwater foundations to fortify wind turbine facilities.

Offshore wind turbines face the formidable challenges of enduring intense winds, waves, and tidal forces in a rigorous marine environment. Additionally, they must counter the corrosive impact of high-salinity seawater, necessitating steel of superior quality compared to its onshore counterparts.

Categorically, the steel plates employed in underwater foundations adhere to specifications encompassing EN, ASTM, JIS, and DNV—amounting to 16 distinct steel variants. China Steel Corporation (CSC) has transcended its legacy in shipbuilding steel plates, successfully introducing steel iterations such as S355ML, S420ML, and S460ML. S460ML steel, specifically engineered for deep-sea deployment, showcases exceptional toughness even in austere conditions with temperatures plummeting to -40℃.

The general plate thickness used ranges from 50 mm to 100 mm. Given the inherent inverse relationship between strength and thickness in traditional structural steel, CSC has strategically invested in cutting-edge technology and equipment upgrades across both the steelmaking and rolling processes.

CSC's strategy aims to augment the toughness of ultra-thick steel plates. This is a necessity for underwater foundations in offshore wind turbine installations.

Furthermore, to fortify the resistance of wind power steel plates against the corrosive impact of potent winds and moisture, copper and nickel (known as anti-rust and corrosion-resistant alloys) are infused during the steelmaking process. This process enhances the overall weather resilience of the steel.

CSC remains dedicated to collaboration with local players in the offshore wind power supply chain. This will propel the robust growth of the offshore wind power sector in Taiwan.

Credit: GWEC