Polyimide (PI) film coverlays are an important material that protects the bendable circuits on flexible printed circuit boards (FPCBs) from being damaged by high temperatures, moistures, pollution and acidic corrosion. It is meant to completely protect the FPCB from harsh environments and allow the FPCB to maintain its bendability and all its functions. FPCB makers usually use PI film or screen printing coverlays to achieve the protection, but both methods still see technological issues that need to be resolved.

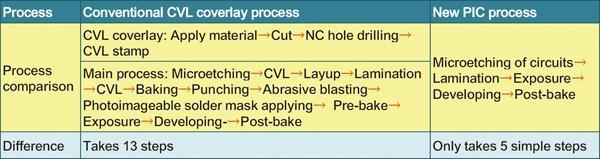

The photoimageable covery (PIC) is the latest solution that Taiwan-based TeamChem Material Company has offered to FPCB makers. Compared to the traditional PI-film coverlay, PIC has many advantages. First, PIC uses a photoimageable process to create holes or reveal solder positions, and it does not need machines to conduct the die-cut process. Therefore it is a more precise, low-cost and time-efficient manufacturing process. Second, PIC can simplify the FPCB's manufacturing process, cutting down the steps to only five, much lower than the 11 seen in traditional processes. This accelerates manufacturing, significantly reducing manpower and power consumption. Third, PIC is not as rigid as conventional PI films, giving it better flexibility to prevent rebound during static bending.

The above-mentioned rigidity issue of the traditional PI film coverlay stems from the PI film's rigidness, which will increase the substrate's rebound strength when the FPCB is bent. Therefore, when an anisotropic conductive film (ACF) is applied onto the FPCB, the PI film coverlay's rigidness will result in some remnant stress on the FPCB after assembly and this will reduce the reliability of the product. However, PIC is created with soft materials that do not contain any rigidness, allowing the FPCB to be free from remnant stress after assembly. Therefore, when a FPCB needs to be laminated using ACF, PIC is the best solution for FPCB makers.

PIC is a soft photoimageable solder resin with a chemical structure that is mainly composed of soft epoxy acrylic resin, a type of material that has long been used in FPCBs. Its heat- and chemical-resistance properties and flexural strength have also been generally recognized. Due to its characteristic softness, it hardly creates bubbles when being mounted, and does not crack even when the substrate and the chip have different stress levels. PIC will change its flexure along with the stress difference.

Compared to FPCB-use soft solder mask ink, PIC has five major advantages:

1. No need for screen printing; clean and odorless; consistent film thickness.

2. Resolves the difficulties of hole-plugging when applying liquid ink onto double-sided or multilayer FPCBs.

3. Its flexural strength is similar to that of FPCB photoimageable ink, but it features better photoimaging capability and chemical resistance.

4. Quick developing, and short cure time during post-bake.

5. Does not include silicon oil-based defoamer, so there will be no pollution problem at the edge of the PCB pad; neither will it pollute the immersion gold and gold plating baths.

PIC completely meets the European Union's (EU) safety regulations, resulting in wide adoption by Germany-based FPCB makers.

FPCB makers' actual manufacturing results show:

1. PIC eliminates the processes of cutting, drilling and punching that are needed to process PI films; increases efficiency and reduces costs.

2. Enhances the alignment accuracy for the coverlay's fast-press process. The accuracy is improved from 0.1mm to 0.025mm.

3. Capable of resolving the excessive glue issue as it adopts the photoimaging method for opening and therefore the glue will not overflow, reducing the excessive glue issue from 0.1mm to zero.

4. PIC is capable of directly replacing fast-press and WF, resolving the problem of poor sealing during the WF process.

Lamination is the most important step deciding the success of PIC process; preventing bubbles from emerging is the most crucial issue. Once the lamination is finished without creating bubbles, the whole PIC process is already half-completed. As for how to prevent bubbles from forming, the hot-press temperature has to be low. TeamChem Material Chairman Dr. Todd Yeh suggests that when a circuit layout is not symmetrical or the circuits are too dense, vacuum fast-press equipment is more suitable to achieve a good lamination result.

TeamChem Material Chairman Dr. Todd Yeh points out that the company's PIC is made under a low-temperature environment, ready for production at FPCB makers' existing facilities and capable of featuring different colors and film thickness. Currently, TeamChem is able to supply matte black, glossy green and yellow PIC in mass volume, while FPCB makers in Germany, Switzerland and China have purchased TeamChem's PIC products for use in high-precision medical and aerospace equipment, tablets, smartphones' communication antenna FPCBs, and FPCBs for light bars.

Commenting on the development of PIC applications, FPCB engineers have pointed out that the conventional method has at least 11 steps - microetching of circuits, layup, lamination, baking, punching, abrasive blasting, photoimageable solder mask applying, pre-bake, exposure, developing and post-bake. But after PIC needs only five steps - microetching of circuits, lamination, exposure, developing and post-bake - saving work, time and manpower. PIC is a great help for FPCB makers who need to compete for orders through cost-down efforts.

Comparison of PIC and CVL processes

DIGITIMES' editorial team was not involved in the creation or production of this content. Companies looking to contribute commercial news or press releases are welcome to contact us.