As Industrial 4.0 and smart manufacturing emerge, the integration of virtuality and reality has become the mainstream. This trend has subsequently brought changes to the landscape of industrial products, from concept design, product design, mold design to manufacturing and production. The process entails CAD models all the way down to different simulations at every stage. Because of its expansive influence, the technology of molding analysis has been employed for more than 30 years and now is highly acclaimed. The application involves commonly seen injection molding, rapidly extending to advanced manufacturing fields, namely smart manufacturing and semiconductor package analysis.

David Hsu, Chairman of CoreTech System, demonstrated that Microsoft Azure offers strong cybersecurity, and lists high-performance computing (HPC) as a critical development strategy, aside from a major upgrade for computing facilities under the hood. Meanwhile, Microsoft also launched a hybrid cloud model for the first time that allows customers to control their own data. Microsoft Azure introduced scalability as required for high performance computing, so customers enjoy high performance computing and asset-light benefits.

More and more manufacturers are in urgent need of molding analysis software to swiftly develop molds, digital twins of products, or even digital twins of materials and machines with a view to enhancing the efficiency and quality of product development. In light of this, CoreTech System, who has gained high reputation with its Moldex3D software, decided to proceed with various value-added services, such as "Azure Connect", "Moldex3D Plastics E-Learning (MPE)", and "Material Hub Cloud (MHC)" which are built upon Microsoft Azure's cloud platform. The goal is to reduce the threshold for users to harness the techniques of molding analysis, while leveraging simulation-driven AI as means of rapidly reinforcing the capacity of smart design and smart manufacturing.

Founded in 1995, CoreTech System helped the plastic industry accelerate product development and decrease the development cost of products and molds at early stages. By laying the foundation on computer-aided engineering (CAE) techniques, CoreTech System initiated Moldex3D, provoking favorable responses as the first of its kind in the global market, which makes 3D molding analysis software real and useful. The number of Moldex3D users is growing and has reached 5,000 customers as of now.

David Hsu, Chairman of CoreTech System, expressed that for over 20 years of Moldex3D applications, their annual revenue maintains robust growth of 10% to 15%. There is no sign of the technology being mature or at a standstill, and this indicates continuously thriving market demands. Plastic and metal are top two industrial materials. Especially when there are more than 100 thousand types of plastic materials with distinct properties, the timeline of product development is easily delayed because it could be significantly difficult in design, processing, and size matching. Therefore, it is essential that users carry out simulation of product and mold design with the help of the molding analysis software to shorten the product development cycle. From this perspective, the fundamentals of Moldex3D are indeed solid.

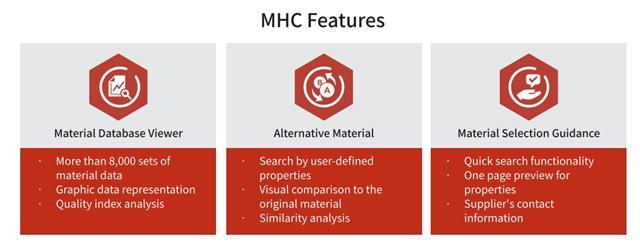

Three features of CoreTech System's MHC include viewing material master data, sourcing alternative materials, and recommending materials for products. David Hsu, Chairman of CoreTech System, pointed out that MHC can be beneficial for molding analysis, but much potential for product design and processing applications.

It is worth mentioning that recent years have seen Moldex3D leap outside of the conventional scope. Instead, it blazed a way in the new business opportunity of semiconductor package analysis, turning into the molding analysis software that takes up the highest market share in the package area. Furthermore, the product is not just used for smart design which it is most powerful for, but extensively to smart manufacturing application. Accordingly, it is a right fit for simulation of flow, warpage as well as material properties and characteristics of machines. Customers are in perfect hands to address processing conditions during manufacturing and production.

As the customer demographics and services have become diverse, the customers' expectations that CoreTech System strives to meet have been broadened. This serves as a driving force to steer away from standalone sales of Moldex3D software. In recent years, CoreTech System successively launched several innovative cloud services, including MPE (Moldex3D Plastics E-Learning) e-learning platform and MHC(Material Hub Cloud) as a database of the properties of processed plastic materials. What's more, Azure Connect solution is also made available for customers to access cloud resources and run Moldex3D for they are enabled to control data on their own. There new offerings are well structured with great values and future trends, all based on Microsoft Azure's platform.

MHC as an incredible aid in accelerating product development

David Hsu suggested that it is customers' demands that motivated CoreTech System to roll out the above products. Take MHC for example. One of the biggest obstacles that customers face lies in the fact that the properties of polymeric materials are non-linear and do not have a fixed parameter for reference. That is why they easily deteriorate as temperature changes or when processed. It is extremely hard to control them. Besides, the popularity of ESG stimulated a wave of plastic recycling. This has led to degradation and broken bonds in polymer within plastic materials, which would affect the stability of molding and make the problem thornier. Considering the issue, CoreTech System spent NT$ 60 million to invest in a material laboratory. On one hand, they can compile the physical properties provided by material suppliers. On the other hand, through constantly measuring and accumulating a substantial amount of data, the company helps customers quickly recognize the characteristics of each material curve. In this way, they are able to identify the most suitable materials, accelerate product development, and avoid high cost.

As of now, the CoreTech material lab has already established more than 8,000 sets of physical property data of materials, and the list is going on. Usually CoreTech System would provide customers with this kind of data as they purchase Moldex3D. However, CoreTech System noticed that demands for this kind of big data of materials are not limited to molding analysis, but reach out to product design. Thus, this year (2022), the company marketed MHC service on the basis of Microsoft Azure so that existing Moldex3D customers, plastic designers, or plastic processors may subscribe to obtain more sophisticated information for design.

"The benefits that MHC brings to customers are in fact beyond our imagination," said David Hsu. For instance, "sourcing alternative materials," one of MHC's capabilities, is devised to select materials with similar properties for further analysis in the absence of the materials that customers desire. With that in mind, many customers draw inferences from the idea, and make use of the system to find similar materials to reduce cost or resolve the crisis of supply chain disruption.

The concept of MPE derives from the experience 4-5 years ago. CoreTech System formulated a training program for customers on a 1-1 basis, but provided that the cost was relatively high, the service has been shifted online and remotely with the launch of Moldex3D University. The industry is undergoing a wave of retirement of senior masters, and this has forced newcomers to shoulder heavy burden when they still lack sufficient experience. Hence, there is a pressing need to count on Moldex3D University and develop knowledge and techniques for molding as soon as possible.

Moving forward, CoreTech System is determined to enhancing the functionality of Moldex3D University to live up to customers' expectations. They look to incorporate more design courses related to materials, machines or processes than just Moldex3D into the new form of MPE service platform.

CoreTech System, who has gained high reputation with its Moldex3D software, decided to proceed with various value-added services, such as "Azure Connect", MPE e-learning platform, and Material Hub Cloud (MHC), which are built upon Microsoft Azure cloud platform. The goal is to reduce the threshold for users to harness the techniques of molding analysis, while rapidly reinforcing the capacity of smart design and smart manufacturing.

Azure Connect implemented to lower the threshold of simulation computing

Speaking of Moldex3D's cloud transition, David Hsu frankly shared that it occurred to him 10 years ago, but it did not work well with promotion as expected. Whether it is Moldex3D or other CAE software, the cloud journey was rugged. Customers not willing to upload the confidential information of their product design was the most challenging part.

It was not until a few years ago that CoreTech System had seen a big turning point. That is to say, Microsoft Azure boasts the most complete cybersecurity and audit certification. The most thorough end-to-end security, covering from identity, encryption, network, SIEM to governance & monitoring across industries and regions, is now within reach for customers in a zero-trust structure. In addition, to play out a large number of CAE use scenarios in simulation, Azure HPC put forth the most cost-effective solution from computing and storage to network powered by the most advanced, optimized technologies. In particular, Microsoft Azure has global presence across more than 66 regions where they can respond to the market needs, fast and properly, from over 5,000 customers of CoreTech System around the world. In the meantime, Microsoft Azure's portfolio, from Azure Marketplace, pre-sales and post-sales technical support to go-to-market planning, has been honed and could be helpful for ISVs to expand their touch worldwide.

Milestones of Azure HPC & AI platform about the investment in high performance computing. In 2021, A100 cluster was among the top 10 supercomputers in the world.

To tap into the trend, CoreTech System brought forth Azure Connect, committed to carving out a niche of "one-click deployment" for customers to easily construct an environment to execute Moldex3D on Microsoft Azure. David Hsu categorized it as the "first-generation Azure Connect" where customers are asked to "bring your own license" (BYOL). Azure Connect is flexible, dynamic, and scalable in case the computing resources are not adequate during operation. Users may scale up for more CPUs, memory, disks and additional features; they may also scale out to increase the number of VM instances, having multiple machines to massively run parallel computing; they may even scale down to zero and pull out necessary OS Images for future rapid deployment when no resource is requested. Microsoft Azure enables customers to control their own data by introducing scalability as required for high performance computing.

Though the "first-generation Azure Connect" puts remarkable benefits in the front of customers, it is restricted by the unscalable number of software license. To overcome the limitation and truly apply the asset-light model to the access to hardware and software, CoreTech System embarked on developing the "second-generation Azure Connect" which sets a license manager for Moldex3D on Microsoft Azure. The company plans to propose a prototype in the middle of the year and formally launch the service in the fourth quarter. After that, Azure Connect users will automatically receive additional pay-as-you-go licenses from the system if they need more, for example, 5 or 10 extra, once filing a request.

Microsoft Azure as a critical accelerator to fulfill three development goals

David Hsu stated that CoreTech System has three development goals to march toward the future. In the first place, based on smart manufacturing, they would take advantage of digital twin to embed simulation computing into customers' design/ manufacturing process, from which more application values are generated. Secondly, CoreTech System will put a lot of effort in the application of semiconductor and electric vehicles, and take the initiative to seek for collaboration with more customers. He further explained that as the era of advanced 3 nm or 2 nm process is approaching, and the challenge against Moore's Law nearly comes to an end, semiconductor manufacturers are turning to package technology to prompt process innovation. They no longer build skyscrapers but establish many communities before they are packaged. Nevertheless, each community carries different component assembly which varies strikingly in properties. Heterogeneous integration could make scenarios complicated and result in issues, such as heat, interference, and deformation. Consequently, Moldex3D is brought into play here to simulate first. The dependence on it will certainly soar. Under the complex semiconductor processes, the need for IT infrastructure in CAE will also exponentially climb up. Azure HPC will work out more optimal solution to the complicated scenarios in heterogeneous integration and IC innovative package.

The third focus is to "train AI with simulation data." The level of difficulty is the highest, so it is not possible to expect results in five years' time. Why does CoreTech System attach great importance to this? Because unlike commercial AI application, people are looking for far more accurate industrial AI in analysis. Nonetheless, acquiring engineering data is costly. The lack of an adequate amount of training data delays the development. Accordingly, it is inevitable that simulation data, coupled with real data, will be utilized for training. The lineups of Microsoft Azure Data Services, namely Azure Synapse Analytics, Azure Machine Learning, Azure Datalake, Azure Data Explorer, and Power BI, furnish customers with data analysis model and engine that are more flexible and on-demand. They will carry on the professional services in the realm of digital twin and AI, thriving together with CoreTech System.

All in all, on CoreTech System's journey of pursuing the three goals, Microsoft Azure will play the role of critical accelerator to assist customers in producing a new form of synchronized, collaborative work flow. Moreover, the simulation capability of Moldex3D is incorporated into the flow. In this way, more participants can conduct optimized analysis very efficiently while stepping closer to the vision of smart manufacturing and IC package.

Learn More

*Probe into the solution to unlock your innovation through Azure's leading high-performance computing

*[Free download of whitepaper] How Azure helps semiconductor industry grow and thrive

*Explore and start your Azure journey