In recent years, the e-commerce has soared because of the exponential growth of Omni channel strategies. As a result, high efficient supply chain management and flexible inventory management have become the key to success for every logistics companies. Companies now grapple with challenges like scattered orders, concentrated arrivals, strict logistics deadlines, and the cost control pressures. They are keen to find out a way to optimize labor costs, enhance transportation efficiency, reduce delivery times, and maximize the benefits of warehousing and logistics. The retail, manufacturing, and e-commerce industries all are reliant on robust logistics systems to drive business growth. Smart logistics has become a key term for industry advancement, driving the logistics industry to accelerate digital transformation, which requires adopting smart logistics management solutions. With the adoption of technologies as big data, artificial intelligence (AI), and the Internet of Things (IoT) , the industry aims to meet the increasingly complex demands of the market.

Traditional warehouse operation in logistics is often labor-intensive, which results in high employee turnover and recruitment challenges. Logistics providers today must be able to respond quickly and ensure accurate deliveries. Meeting customer demands requires companies to devise methods to address staffing limitation, minimize the time from receiving goods and orders to shipping, and provide excellent customer service. To achieve these goals, companies must embrace smart logistics solutions.

Driven by information technology, smart logistics integrates perceptual into various facets of the logistics process, including transportation, warehousing, packaging, loading and unloading, distribution processing, and delivery. Collect data from these operations and analyze it to make optimal decision. This field encompasses elements such as equipment sensing, data processing, intellectualized analysis, and decision optimization. However, when we consider the diverse demands of deploying logistics deployment, it becomes the key element that certain challenges need to be addressed. For instance, as companies' image capture quantities requirement and amount information analysis , numerous cameras must be applied in the field, which often necessitates high-speed image transmission and on-device artificial intelligence image recognition. Unfortunately, standard industrial computer (IPC) specifications typically struggle to meet all these diverse configuration requirements simultaneously.

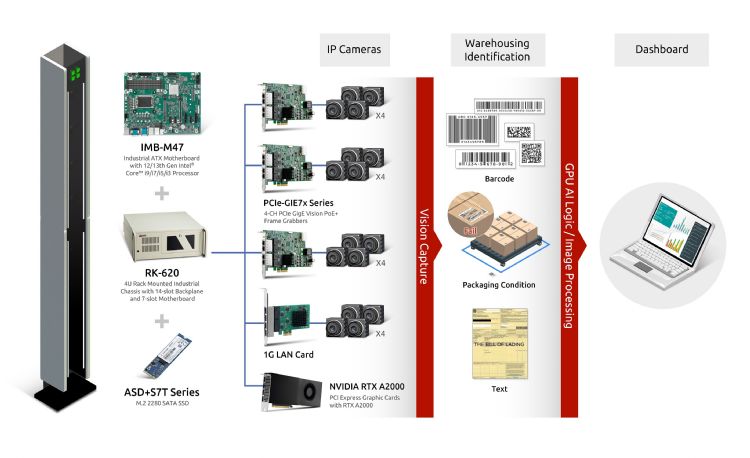

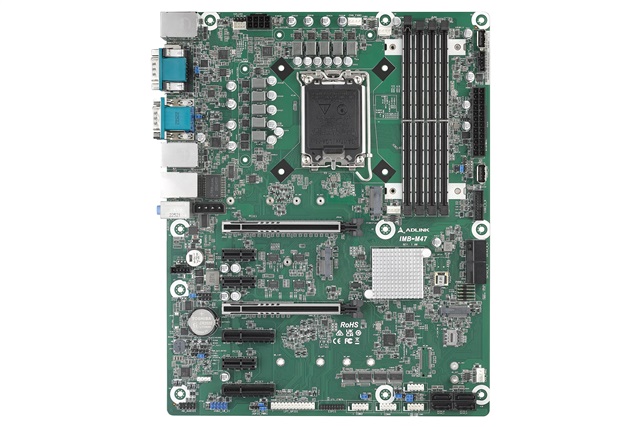

In contrast, ADLINK's IMB-M47 industrial ATX motherboard, powered by Intel 13th/12th Gen processors (Raptor Lake-S/Alder Lake-S), not only leads the industry with DDR5 , Gen4 SSD, three 2.5 Gbe LANs and high-speed I/O design to boast high transmission speed but includes 7 PCIe slots for add-on equipment and PCIe Gen5 to fulfill edge computing abilities. As a result, a single motherboard can help companies to break through the bottleneck, enable the industry to integrate large quantities cameras at edge device to capture critical logistics data, conduct AI image computing process at speed of up to 64 GB/s, storage and retrieve vital logistics information rapidly to display real-time information and notify client systems.

Empowering Key Image Capture and AI Computing with PCIe Expansion Advantages

Jeremy Huang, Senior Product Specialist of ADLINK's Edge Computing Platform Product Center, highlighted that the pandemic prompted logistics companies to adopt smart technologies. Factors as reduced staffing in production lines, advanced AI image recognition, and climbed in small packages from e-commerce. On the other hand, face challenges with staff shortages and inaccurate issues in traditional RFID or manual scanning, which cause challenges in inefficient warehouse management, inventory control, and material transportation.

The utilization of machine vision technology is expected to deliver comprehensive enterprise information through real-time recognition, data generation, computing, and analysis. This technology will enhance operation and enable personnel to focus on situation correlation judgment and problem resolve. It will present operation processes on the control platform and execute the most efficient resource to maximize delivery timeliness, allocate the location of goods and personnel. To sum up, a critical objective is to employ smart logistics solutions to ensure that companies, customers, and suppliers always access real-time information about goods.

As this trend continues to evolve, ADLINK's role in the logistics and warehousing industry has grown in significance. Jeremy Huang explained that the advancement of CPUs and GPUs have significantly improved computing performance in the past three years. Coupled with increasingly sophisticated algorithms, logistics companies have become more confident in AI machine vision and are increasingly willing to adopt it. As a result, companies have begun commissioning smart logistics system integrators (SIs) to drive smart logistics projects.

For a common application scenario, System Integrators (Sis) establish a smart warehouse control tower with up to 16 cameras installed at the customer's warehouse entrance. When a forklift enters with goods, the solution identifies the items on the pallet from four directions and immediately raises an alert on issues such as damaged packaging, missing barcodes, or incorrect quantities. ADLINK IMB-M47 ATX motherboard boats 7 PCIe slots, enables SIs to configure quantities image capture and network cards to connect 16 cameras, facilitate the seamless capture of critical images like cargo labels, bills of lading, and package. SIs can also install a GPU card to compute image and enable smart image analysis. Additionally, the IMB-M47 offers numerous DIO interfaces, including 8x GPI and 8x GPO, to connect external sensors to provide real-time alerts. Obliviously, ADLINK IMB-M47 is the one of the very few motherboard on the market, which is capable to support 16 cameras by one single motherboard. Hence, startup SIs based in the United States have begun adopting it.

Architecture diagram of a smart logistics management system using the ADLINK IMB-M47 ATX motherboard

Enhanced data processing and transmission speed to ensure immediate and reliable data transmission

Additionally, ADLINK IMB-M47 demonstrates several other impressive features. For instance, it efficiently supports the simultaneous transmission of image data from 16 cameras through PCIe x4 (Gen4);The utilization of DDR5 4800 DIMM memory, couple with PCIe Gen4 M.2(1.5 times faster than the current mainstream DDR3 and three times faster than traditional SATA III SSDs), 2.5 gigabit LAN with rich high-speed I/O to achieve high-speed data transmission.

IMB-M47 is equipped with a Gen5 PCIe x16 expansion slot, offering double the computing speed and bandwidth compared to mainstream PCIe Gen4. The remarkable computing power allows customers to deploy GPUs at edge devices for direct AI image processing as needed.

ADLINK launches the IMB-M47 ATX motherboard featuring 7 PCIe slots and supporting DDR5 memory

Hsin-Chen Lin, Product Manager of ADLINK's Edge Computing Platform Product Center, highlights that while many motherboards on the market offer Intel 12/13th Gen processors, most syill rely on DDR4 or PCIe Gen4. In contrast, the IMB-M47 stands out as an all-in one solution, embracing the latest DDR5 and PCIe Gen5 configuration. This makes it the ideal choice for smart logistics applications, capturing a significant share of the market.

Traditionally, when goods arrive at a warehouse, forklifts would unload pallets into a designated area. Staff would then manually scan and categorize the goods using barcode scanner, a process taking tens of minutes before shipping. Implementing ADLINK IMB-M47 in smart logistics management introduces automation, data integration, and intelligence. This facilitates "fast logistics" where data processing and exchange occur rapidly, minimizing shipping wait times. The impact of this optimization is remarkable.

Conclusion: The Tech-Powered Future of Logistics

Technology is no longer just a tool, it's the driving force behind the evolution of logistics management. With adopting the latest technology solutions to obtain real-time tracking, data analytics, automation, and AI, companies are unlocking unprecedented levels of efficiency, visibility, and sustainability. The logistics landscape is being reshaped, enabling companies to meet customer demands faster, reduce costs and navigate complexities with confidence. As technology continues to advance, the possibilities for optimizing supply chain efficiency are boundless, ushering in a new era of logistics excellence.

Learn more about the ADLINK IMB-M47 or contact ADLINK for more information about its products and solutions.